Laser Cartridge Schematic Showing Major Components

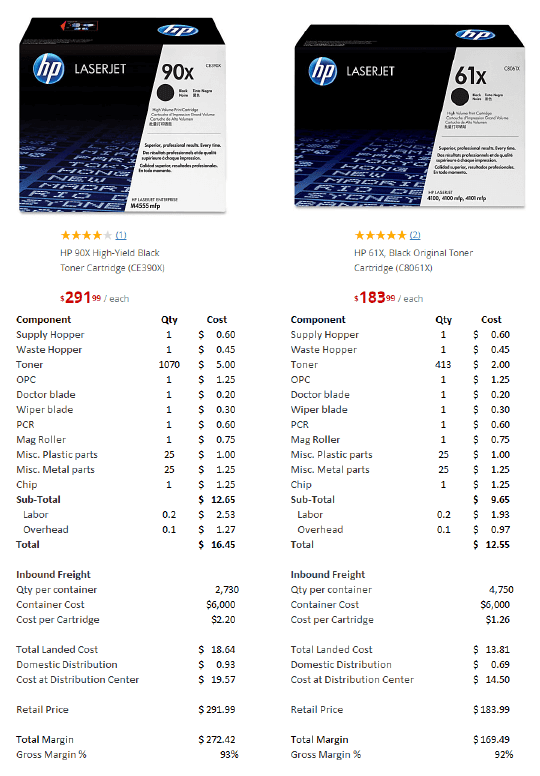

The material cost in a typical laser cartridge is around $15 to $20. Of course there are variables between cartridges, some have more and some have less toner, some are fully integrated structures (as shown here) and some are not. The two examples selected for these examples show a 24,000 and a 10,000 page yield style. However, cartridges can yield anywhere from as little as 1,500 to as many as 40,000 pages, and typically, the hardware selected is based on the customer usage requirements.

A cartridge used in a high volume business environment may have as much as thirty times the yield of a small personal printer cartridge but would be priced at only around four times that of the lower yield cartridge. For the most part the components of a low yield cartridge compared to a high yield cartridge are similar. The amount of toner and the size of the molded parts will be different but the overall technology and component parts are very similar.

Broadly speaking, most cartridges manufactured by the OEMs have a delivered cost somewhere between $8 and $25 depending on the page yields.

Here are two examples showing the listed prices of OEM brand products as of April 2016 alongside the estimated manufacturing and distribution costs:

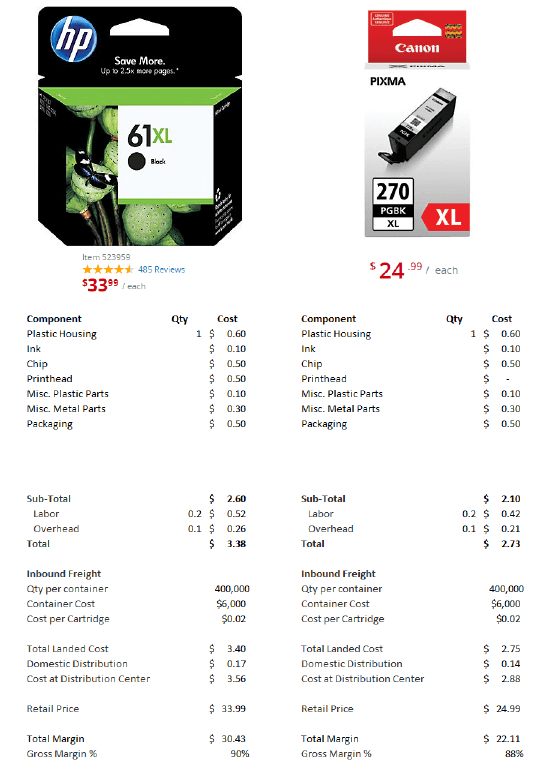

Ink jet printing is enabled through deployment of sophisticated technology that’s evolved over the last 40-50 years. After going mainstream in the mid to late 1990s it’s quite incredible how sophisticated and advanced today’s technology is, both in terms of print quality and speed of output. Millions of dollars have been invested by the OEMs to get the technology to where it is today.

The material cost in a typical ink cartridge is $2 to $3 with most of the cartridges manufactured in highly automated facilities in low labor-cost locations around the world. Because of their compact design and relatively low weight, the cartridges can be transported around the world at very low “per-piece” freight costs.

Of course, some ink cartridges have more ink than others, some cartridges are multi-color and some just one color, so actual costs will vary to some degree depending on the design. However, regardless of these variations, most OEM cartridges cost very little to manufacture and most OEM sell prices are very high in relation to the manufacturing cost.

As can be seen from the two example costed bills of materials below, the cost between a cartridge with an integrated print-head and one without are not significantly different, but it’s not uncommon to see a 30%+ pricing differential between the two as a result of different aftermarket competitive pressures.

Here are two examples showing the listed prices of OEM brand products as of April 2016 alongside the estimated manufacturing and distribution costs:

Laser cartridges that cost between $15 and $20 to get from the offshore factory to local distribution centers across the United States for resale between $200 to $300 doesn’t seem right.

Ink cartridges that cost between $3 and $4 to get from their factories to local distribution centers for resale between $25 and $35 also doesn’t seem right.